Process Integration Assignment: Order Fulfillment Procedure ofGeneral Motors

Question

Task:

Process Integration Assignment Task:

Case study on General Motors Inc.

General Motors Company Inc., commonly known as GM, is an American multinational automotive corporation headquartered in Detroit, Michigan, and among the world's largest automakers by vehicle unit sales, employing 202,000 people and doing business in some 157 countries. General Motors is divided into five business segments: GM North America, GM Europe, GM International Operations, GM South America, and GM Financial. General Motors produces cars and trucks in 37 countries.

Today, the top three individual GM shareholders are Mary Barra,as of her most recent filing with the SEC on February 15th, 2018, Mary Barra is General Motors’s largest individual shareholder, holding a grand total of 520,608 shares of GM, Mark L. Reuss is the current Executive Vice President of Global Product Development, Purchasing and Supply Chain at GM. As of that previously-mentioned February 15th, 2018 SEC filing, Reuss claims the vaunted spot of second-largest individual GM shareholder with 203,934 shares in the company and Dan Ammann is the current president of General Motors; he has held the position since January 2014. Before that, he enjoyed laboring as the company’s CFO and executive vice president. As of the February 15th, 2018 SEC filing, Ammann is the third-largest GM shareholder, he holds 195,228 shares. Since, being top shareholders, these individuals’ “own” significant chunks of the company.

General Motors owns and operates a plethora of automobile brands across the globe. These brands include Chevrolet- mass market models, Buick, More expensive models GMC targeting the luxury market, Cadillac, Baojun, Holden, Isuzu, Jie Fang, Opel, Vauxhall, and Wuling. To understand the competitive environment of the small car market, including market commonalities and resource similarities, General Motors should perform a competitor analysis. Car companies competing in various market segments, including SUVs, trucks, and compact cars, are referred to as multimarket competition. General Motors' strategy is to deliver safer, simpler and more sustainable transportation solutions for our customers. In doing so, we'll realize our vision for personal mobility — we'll help the world see a future with zero crashes, zero emissions and zero congestion.

GM's operating profit remained healthy. The company reported an operating profit, which is earnings before interest and taxes, of $8.4 billion for the year, including $105 million in the fourth quarter. That's down from $11.8 billion in 2018 and $8.4 billion for the fourth quarter of that year. In 2019, an equity income of $1.1 billion from China joint ventures was added to GM's earnings before interest and tax (EBIT). Nevertheless, GMI's revenue contribution still totaled as much as $16 billion with 995,000 vehicles delivered in 2019, making up nearly 12% of the company's entire sales. To understand the competitive environment of the small car market, including market commonalities and resource similarities, General Motors should perform a competitor analysis. Car companies competing in various market segments, including SUVs, trucks, and compact cars, are referred to as multimarket competition.

GM acts in most countries outside the USA via direct subsidiaries, but in China through 10 joint ventures. GM's OnStar subsidiary provides vehicle safety, security and information services. In 2009, the company shed several brands, closing Saturn and Pontiac, and emerged from government backed reorganization. In 2010, GM made an initial public offering that was one of the world's top 5 largest IPOs to date. GM returned to profitability in 2010.

Assume the following scenario in our case study of integrated processes. Petroman Corporation (PC), a General Motors Company customer in GM North America, has ordered 800 bottles of GM Dexos Motor Oil (GMD- 5W-30) from GM. Because PC is located in the Western U.S. sales organization, GM will ship the GM Dexos Motor Oil from its San Diego plant, which iswarehouse management enabled. We will make the following assumptions:

1. The San Diego plant has 200 bottles of GM Dexos Motor Oil (GMD- 5W30) in stock valued at a moving average price of $15.43 each.

2. The Miami plant has 1,500 bottles of GM Dexos Motor Oil (GMD- 5W-30) in stock valued at a moving average price of $15.25 each.

3. GM can purchase bottle of GM Dexos Motor Oil (GMD- 5W-30) from Shell Motor Oil at $14.95 each.

4. Petroman Corporation (PC) has sent GM a purchase order (PO) for 800 GM Dexos Motor Oil.

5. GM sells GM Dexos Motor Oil for $30 each.

6. GM Dexos Motor Oil (GMD- 5W-30) must be reordered when there are 250 or fewer left in inventory. In addition, the GM Dexos Motor Oil (GMD- 5W-30) must be purchased in quantities of 1000 bottles.

Based on the following six logical groupings of process steps, identify and discuss the steps in the integrated process that include the procurement, fulfilment, and IWM processes. Analyze the financial and material impacts of the various process steps:

1. Fulfillment process—initial steps

2. Procurement process—initial steps

a) Procurement process—external procurement/In the event the Miami plant is unable to fill San Diego’s requirement for GM Dexos Motor Oil (GMD- 5W-30).

For the points 3-6 assume that GM has selected the Procurement process—external procurement option.

3. Warehouse management steps related to procurement

4. Fulfillment process—shipping

5. Warehouse management steps related to fulfillment

6. Fulfillment process—concluding steps

Answer

Fulfilment process – initial steps

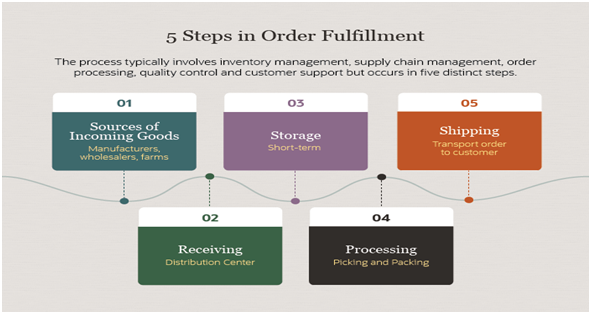

The process of order fulfillment examined in this process integration assignment mainly occurs in more than one distribution centre of General Motors. It typically involves proper management of inventory, efficient supply of chain management, processing of an order, quality control, and customer support to identify problems from customers' perspective.

According to the Author Schoenherr(2019), products coming from a third party, or any other company or warehouse-like fluid product or cars as digital information from the database or in some other variety of forms. In any case, the incoming stock supplies need to be counted, proper inspection and inventoried to ensure the required quantity was received and the quality is standard. SKU' are used on the delivered products, which helps in the storage process and retrieve them later from storage when demands arise. Goods received in the fulfilment point or centre at that time they are adequately inventoried quickly and then disbursed. After this step, an order processing system indicates the picking of product and packaging of newly received product order. After this step, a group of picking teams choose items from the warehouse as per demands on packaging slip and After successfully picking the product as per the instruction like SKU's colours and quantity location in the warehouse.

Procurement process -initial steps

As per the 's argumentof Lee et al. (2018), the General Motors procurement process includes thousands of suppliers. The conversion of purchasing into electronic web-based software will minimize the cost of products and simultaneously cut the ordering cost for General Motors. It will boost significant improvement in the procurement process and bring well-informed quality forecasting and planning for General Motors and its suppliers. The process of digital procurement contains a request for digital quotations, financial analysis of supplies, risk analysis and verified e-signatures. All these processes go beyond purchasing, which requires minimal human assistance.

Procurement process -external environment

The external procurement of general motors includes one-time procurement where the order is placed according to the demands of goods and services where the demand is not regular. Extended agreements with the vendors and the goods and services will be shipped by generating release orders (Stopkaand ?upták,2018). It is going to give flexibility in terms of price negotiation with the vendor. This kind of contracts always has date validation. The process of outside procurement also takes place when the demands of the products require urgent, and then the order is fulfilled according to the party's timeline.

Warehouse management steps related to procurement

To include an efficient warehouse management system, a software program must be selected as per the warehouse's demands. An efficient ERP system that compiles all the units in an organisation plays a very pivotal role for a successful enterprise (Ku?era,2017). By using the right system, it is very beneficial to launch cooperation among units, eliminate waste, make quicker and better decisions. Adopting an ERP system is a very prominent investment decision for an organisation like General Motors; therefore, detailed attention is required for selecting the right system.

Labelling line this process is very vital like machinery and the manual labour. The machinery part includes selecting a barcode printer. There are various kinds of bar code technologies, but the thermal-based barcode printers require less maintenance and prints faster simultaneously prints faster while maintaining print quality. The Manual Labour process includes main three components where the labelling methods takes place like arranging, unpacking, labelling, packaging and final inspection of the products.

Fulfilment process shipping

The initial steps of fulfilment includestock the inventory in the General Motors warehouse, inspecting the inventory, managing and labelling the inventory. After the receiving part is done, the next task will be shelving the inventory and requiring a close eye to which items come in and out so that the time order can be done without delays (Somboonwiwat and Supeekit, 2019). After managing the inventory, the order is picked up from the shelf, then getting shifted to the packaging station, damages inspection, then packaging and moving to the shipping destination. Depends on the size, specific requirements and weight of the order, then the best shipping strategies are determined primarily a third-party vendor is contracted to fulfil this process.

Warehouse management steps related to fulfilment

Proper and efficient management of warehouse includes right shipping carriers, technology and delivery points as well simultaneously selecting the best warehouse which is going to meet future demands and growth for the General Motors Company (Khuan and Swee, 2018). Together implementation of all these things is going to help in inventory more effectively, efficient packaging of boxes quickly and timely delivery on time. Effective warehouse help to store separate SKU in a designated storage location like in a bin, shelf or pallet, which makes sense in term of the design of the warehouse. Once the proper inventory in place, an efficient management system assists in pinpointing the specific location of the SKU so that it can be accessed quickly. Accurate management of the warehouse helps General Motors to keep tabs on real-time inventory management.

Fulfilment process—concluding steps.

To run the fulfilment process effectively is to integrate it with other business-like stocks, accounting and control, and Integration of various systems within the organisation and other associated business partners is going to be essential for smooth and efficient operation. For instance, linking accounting software with the shipping department can also going to speed up the order process, which helps workers to check the status of payment and address intricate details quickly and efficiently (Žuni? et al., 2018). This also needs to be repeated across multiple platforms, which is very much required for greater accuracy and efficiency, mainly through automation. The other important aspect of this method is to ensure that all the order obtained through various mediums needs to be put to one channel like a phone. The online mail system requires being treated identically and put into the same system. By emphasizing this part of the method, an organisation like General Motors can mitigate the risk of misplaced or loss of order.

Reference List

Khuan, L.S. and Swee, M.F.S.H., (2018). Technologies for Procurement: Current Trends and Emerging Trends. Emerging Technologies for Supply Chain Management, 4, pp.45-61. https://www.academia.edu/download/58971642/Ch2_Emerging_Technologies_for_Supply_Chain_

Management_Robiics_in_SC20190420-115343-1qe5whi.pdf#page=53

Ku?era, T., (2017). Logistics cost calculation of implementation warehouse management system: a case study. In M.A.T.E.C. Web of Conferences. Vol. 134 (2017): 18th International Scientific Conference-LOGI 2017. EDP Sciences. https://dk.upce.cz/bitstream/handle/10195/69936/LOGI_2017_Kucera.pdf?sequence=1

Lee, C.K.M., Lv, Y., Ng, K.K.H., Ho, W. and Choy, K.L., (2018). Design and application of Internet of things-based warehouse management system for smart logistics. International Journal of Production Research, 56(8), pp.2753-2768. https://minerva-access.unimelb.edu.au/bitstream/handle/11343/192650/Ho%20-%20Design%20and%20application%20of%20Internet%20of%20Things.pdf?sequence=1&isAllowed=y

Schoenherr, T., (2019). The evolution of electronic procurement. In The Evolution of Electronic Procurement (pp. 33-46). Palgrave Pivot, Cham. https://link.springer.com/chapter/10.1007/978-3-319-93985-8_3

Somboonwiwat, T. and Supeekit, T., (2019). Strategic Procurement Process For Multiple Items In A Supply Chain. In E.C.M.S. (pp. 254-260). http://www.scs-europe.net/dlib/2019/ecms2019acceptedpapers/0254_simo_ecms2019_0006.pdf

Stopka, O. and ?upták, V., (2018). Optimization of warehouse management in the specific assembly and distribution company: A case study. NAŠE MORE: znanstveni ?asopis za more i pomorstvo, 65(4 Special issue), pp.266-269. https://hrcak.srce.hr/file/304719

Žuni?, E., Delali?, S., Hodži?, K., Beširevi?, A. and Hindija, H., (2018), November. Smart warehouse management system concept with implementation. In 2018 14th Symposium on Neural Networks and Applications (NEURAL) (pp. 1-5). IEEE. https://www.researchgate.net/profile/Kerim_Hodzic/publication/329901029_Smart_Warehouse_ Management_System_Concept_with_Implementation/links/5c2226d2299bf12be398f3a3/ Smart-Warehouse-Management-System-Concept-with-Implementation.pdf