(CBE6385) Operations and supply chain management assignment on supply chain issues at Marks & Spencer

Question

Task: Create anoperations and supply chain management assignment from an Organisation of your choice focusing on a problem relevant to Operations Strategy/Management or to Logistics & Supply Chain Strategy/Management. Critically discuss and analyse the pertinent issues in the case study of your choice.

Answer

Introduction-

Brief description of the company and operating field-

Marks & Spencer is one of the leading British multinational food and clothing retail companies which started operating in the year 1884 and is presently headquartered in London (Marksandspencer.com, 2022). Additionally, it is required to mention that quality, innovation & trust, value, and service are4 the main values of Marks &Spencers which is helping the farm to deliver quality products and services to its customers (Corporate.marksandspencer.com, 2022). Being a multinational company Marks and Spencer is collecting revenue from multiple countries across the world.

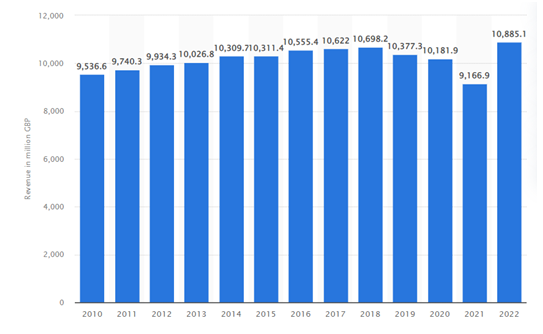

According to the operations and supply chain management assignmentit is found that there are more than 1000 stores across the UK and nearly 450 Marks & Spencer stores are operating internationally which range from court shop home stores outlet stores as well as convenience stores (Statista.com, 2022). This is indicating that the operations and supply chain management assignment organization is involved in multiple dimensions of the retail industry which includes merchandise in grocery products, supermarkets, home decor items, the fashion industry and food halls. Reportedly, the present revenue of Marks &Spencers stands at 10885.1 million GBP in the 2022 financial year which is higher than the previous year (Statista.com, 2022). Another study also uncovered that throughout Britain Marks & Spencer is well known for its invaluable departmental home goods shops as it was voted as the “second most popular store in the home department across the United Kingdom” (Statista.com, 2022). Apart from that, it is required to mention that the operations and supply chain management assignmentorganization is well known for the high-quality product they offer in their food and grocery section however presently due to the sum supply chain issues the firm has faced a range of difficulties.

Aim and operation carried out for the operations and supply chain management assignment

The main aim of this operations and supply chain management assignmentis to evaluate supply chain issues which have been faced by Marks and Spencer. In this regard, a brief description of the current situation had been provided through clear identification of problems. Apart from that financial last caused by these issues has also been demonstrated in this operations and supply chain management assignmentreport. Followed by this possible solution to identified issues presented based on literary evidence. On the other half, this operations and supply chain management assignmentreports proposed possible solutions for the new prostitute of change has been outlined with justification. In the end, a brief description of the implementation plan has been presented with a time scale, milestones and schedule. Finally, the conclusion of the key findings and recommendations for the problem discussed in the operations and supply chain management assignment report is presented.

Description of the current situation in the operations and supply chain management assignment

Clearly describing problems faced by Marks & Spencer-

The main problems encountered by Marks and Spencer throughout their food supplies are present below in the operations and supply chain management assignment:

Food supply chain sustainability issue-

It is required to mention in the operations and supply chain management assignmentthat are typical food supply chain consists of sourcing raw materials production food processing packaging activities storage maintenance-distribution to retailers and redistribution to consumers which involved ranges of transportation. Shipment delay and lack of traceability are one of the main reasons which are associated with the food supply chain of the retail industry (Sunny et al. 2020). In the case of Marks & Spencer, it is noted that the firm authority encountered the issue of a “stock delay” of around 3 weeks in the second half of 2021 only in the core areas of the UK (Bbc.com, 2022). More to the context it is noted that Marks & Spencer started facing supply issues after Brexit as suppliers from UK and EU countries were not prepared for the new paper works (Bbc.com, 2022). As a result of the legal restrictions, the entire supply chain process witnessed delays and put the firm under stress in terms of stock management. On the other hand, it is noted in the operations and supply chain management assignmentthat the modern food supply chain of Marks and Spencer relies on 7 a day food supply system but after the pandemic, the suppliers move to standard officers which are from Monday to Friday (Corporate.marksandspencer.com, 2022). As a result of it, the food supply chain of the operations and supply chain management assignment organization started witnessing significant disruption in their import scheduling because it resulted in an HGV driver shortage. Jaipur it is indicating that restricting regulation of import and export diverse shortage stock management issues resulted in food supply chain disruption of Marks & Spencer.

Lack of effective worker representation-

Employee representation refers to the rights of employees to seek or demand a union which helps them to represent their purpose in terms of negotiation with the upper management body (Kochanet al. 2019). In the case of M&S, operations and supply chain management assignmentstudies have found that due to the lack of effective worker representation they are facing issues associated with wage negotiation, additionally, work-related benefits and working conditions are also being compromised (Oxfamilibrary.openrepository.com, 2022). As a result, frequent employee unrest is coming to the fore and suppliers are encountering challenges. Apart from that, it is found that as suppliers are not getting the opportunity to access universal workplace rights which demand protection for suppliers they are feeling less valued within the organisation which is eventually resulting in a lack of commitment in difficult situations (Oxfamilibrary.openrepository.com, 2022). Based on the above finding it can be stated in theoperations and supply chain management assignmentthat the supply chain of M&S lacks supplier union power and needs expertise so they can accelerate workers' and suppliers' interests.

Issues of communication-

Communication has an important role in the entire business operational process. In recent times it is noted in the operations and supply chain management assignmentthat due to the impact of the external environment global food retailers are facing issues to manage their supply chain activities (DuHadwayet al. 2018). Additionally, a similar study also highlighted that poor communication is the most common issue encountered in the shipping and logistic activity of the retail industry because of the lack of agile adaptability to the change management process. After serving 11 sites of Marks & Spencer food manufacturing sites it is found that the quality of communication between team members and managers is worsening over time and putting the workforce under high pressure (Oxfamilibrary.openrepository.com, 2022). Additionally, the same operations and supply chain management assignmentreport also highlighted that in some UK food manufacturing sites managers have reported that expensive ingredients were wasted after workers accidentally dropped them on the floor. On the contrary, workers also said that as the lines were running too fast in order to meet unreasonable star get the staff was not able to match the speed which lead to misunderstandings and accident occurred (Oxfamilibrary.openrepository.com, 2022). On the other hand, it is found in the operations and supply chain management assignmentthat workers are frustrated with teaching agency stops about their job and how to prevent accidents at the workplace but the higher authority is not focusing on improving communication between the upper management level and team members. This is leading to major communication issues among suppliers, team members and upper management level.

Financial loss caused by these problems-

Figure 1: Revenue of Marks & Spencer

(Source: Statista.com, 2022)

After evaluating evidence regarding the supply chain issues of M&S it is noted in the operations and supply chain management assignment that Marks and Spencer encounter the issue of food stock delay of more than 3 weeks which resulted in a 17 million loss in the same period (Statista.com, 2022). Apart from that, it is noted in the operations and supply chain management assignmentthat due to the shipment delay food products which have limited shelf-life are wasted in large amounts and multiplied by the amount of loss. Not only that due to the delay in the raw material resourcing process the customer satisfaction rate decreased and this fact eventually makes a negative impact on the revenue generation process. Apart from that, at the end of the financial year, 2019 Marks and Spencer encountered a loss of 180 million caused by food supply chain disruption (Bbc.com, 2021). As a result, the total revenue of M&S started dropping from the year 2019 and it reached its lowest point in the year 2021 which is 9166.9 million GBP which is 900 million pounds lower than the previous year (Statista.com, 2022). Apart from that, it is noted in the operations and supply chain management assignmentthat clothing and home sales have decreased by 5.5% during the first half of the 2022 financial year (Logisticsmanager.com, 2022). This finding is indicating that the authority needs to gain control over their food supply chain to maintain their profitability as well as to maintain the sustainability of the operational process. Possible solutions mentioned in the operations and supply chain management assignment Analysing and evaluating data and proposing possible solutions for identified problems- In order to solve issues in the food supply chain two main strategies are recommended which are as follows in the operations and supply chain management assignment: Vertical integration in the supply chain-

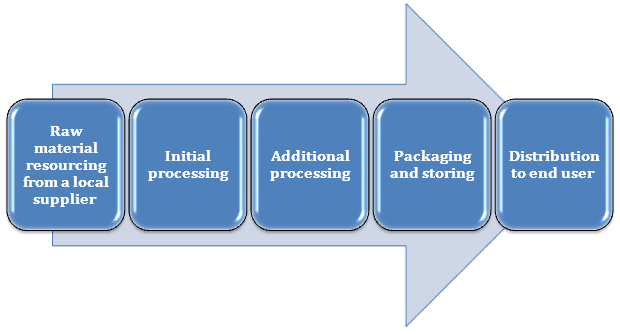

Figure 2: Process Chart of Vertical Integration

(Source: Created by Author)

Vertical integration within the supply chain refers to the particular approach that allows one business organization to enhance its supply chain facility through efficiency enhancement. In a similar context, it is found that by integrating the supply chain vertically Walmart is able to minimise supply chain operating costs and gain extra control over the distribution process (Marusaket al. 2021). Hence, to reduce supply chain operation costs, and reduce time delay M&S can follow a vertical integration strategy as this will not only help in cost reduction but would help in minimising food waste by enhancing supply chain speed. Inclusion of local supplier in the M&S supply chain as per the operations and supply chain management assignmentwould help the authority to minimise “stock delay” issues, especially for food items and they will be able to meet customer need timely.

Communication improvement-

Supplier communication improvement is a critical task as each supplier possesses a different perspective which generally does not match with organisational objectives. Alshuridehet al. (2022) stated in the operations and supply chain management assignmentthat integrating suppliers which share common values as an organisation can help one firm to meet its long-term supply chain goals by building a strong and trusted relationship. Additionally, this study mentioned that by sharing information with suppliers in real-time both parties can complete supply and sourcing activity within facing any major issues caused by communication gaps (Birasnavet al. 2019). However, clear expectations need to be determined before that as it increases the accuracy of the reporting system and improves communication with suppliers. Birasnav and Bienstock(2019) stated in the operations and supply chain management assignmentthat proactive actions, regular meet-ups, and utilisation of technology assist one business organisation to improve overall supply chain communication. In recent times, it is found that Nike has implemented 3D printing, IoT, and Cloud technology which is reshaping supply chain activity as it is enabling real-time communication by improving transparency and reducing lead time (Kabiraj, 2022). However, it is found from the operations and supply chain management assignmentthat M&S is already implemented advanced technologies to optimise communication even under stressful situations.

Proposal for a new procedure or change-

The justification behind the selection of specific solutions-

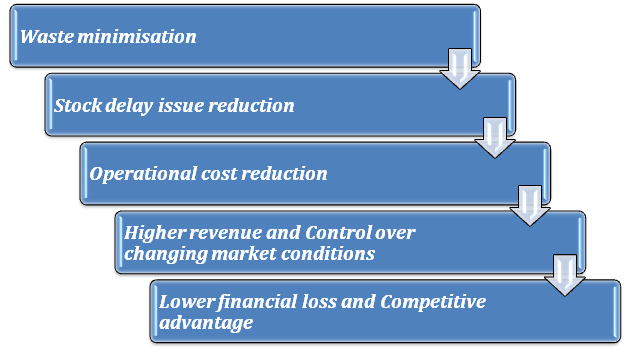

Figure 3: Benefits of Proposed Solution

(Source: Created by Author)

The development of a trusted partnership with a supplier is one of the core values of Marks and Spencer because it assists to carry out the entire operational process and provides support to people and local communities (Esoimeme, 2020). However, in recent times it is noticed in the operations and supply chain management assignmentthat due to the unprecedented impact of Covid 19 pandemic Marks &Spencers are facing issues across their food clothing and home business supply chain but the supply chain issues are associated with the food business which is making a considerable negative impact on business. Especially, issues of sustainability across the supply chain are making an impact on its finances, therefore, this issue has been prioritising to improve the entire business operation of M&S. Studies have found that after completing vertical integration through the supply chain one business organisation gains the ability to reduce operational costs, reduction of food product waste which will eventually provide greater control over the supply chain (Kabiraj, 2022). Finally, it can be stated in the operations and supply chain management assignmentthat M&S would gain greater control over supply chain activity and eventually this would deliver a competitive advantage even in a turbulent situation. Other ideas have been rejected because they would add extra cost to the firm which can be more challenging in this situation where M&S is dealing with millions of financial losses.

Description of the new situation in the operations and supply chain management assignment

M&S has planned to evaluate its overall working process under the leadership of the new CEO for which several changes in the decision-making process are taking place.

The gist is one of the logistics providers for M&S foods with contract terms up to 2027. According to Green, (2022), Gist, earned a profit of £55m of which the maximum has come from M&S as duty fees last year. As per the operations and supply chain management assignmentfindings, the retailer explains higher costs in the food supply chain are the primary result of the organizations unable to provide products at a competitive price as other rivals are doing. The management agrees that the complex storage and logistics network has further resulted in raising the value of products. Some of the products required specific temperatures to preserve their quality which brings the price of other goods to rise. Up till now, Gist provides a majority of logistics services to M&S with 10 secondary and 8 primary distribution centres in the UK and Ireland. Higher authorities of M&S believes has the company had not fallen under a legal contract with the Gist more profits would have come through and the company could have invested in other technological advancements that are required. Contractual terms with the Gist are impacting relations with other potential partners for M&S for which M&S is planning to acquire Gists and all its operations for a whooping deal of £255m (Green, 2022). As per the operations and supply chain management assignmentthe group is planning to upgrade its inventory system by digitising stocks and inventory reports. Centralised monitoring and distribution of food items are one of the strategies that M&S is planning to implement from onwards.

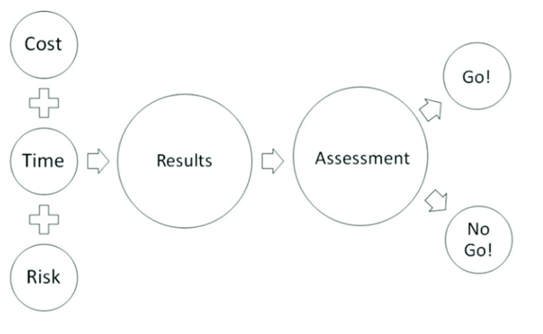

Figure 4: Risk Assessment Flow Chart

(Source: Varsakeliset al. 2020)

‘Vangarde supply chain’ programme launched by the group in 2020 marked an efficient process for stock management and refilling of stocks to gain sustainability in the business (Green, 2022). The higher management is working further to reduce wastage and overstock issues faced during 2020. It is found in the operations and supply chain management assignmentthat the company is working to produce effective processes to sustain availability which can support supply and storage over longer periods. In addition to that, the organization is targeting to reduce its wastage and stock losses by implementing an effective distribution chain system. Food items which are overstocked will shift immediately to regions with low availability. The entity for this is working to infuse new advancements in forecasting, ordering, space range and display systems where customers can have a better view of the product catalogue and display which will ensure higher sales and low wastage of goods (Schleper et al. 2021). As per the operations and supply chain management assignmentapart from that procuring food supplies through local sources will reduce trade tariffs that the entity was paying till now bringing down the effective costing food products lower benefitting customers. The retailer is working to offer more variety in food products in one place which will surely pool customers to market from the stores. Upgrade of technology and transportation system while automating most of the processes to reduce costs in between will help M&S to rise from the issues of ineffective supply chain (McGrath et al. 2021). It is found from the operations and supply chain management assignmentthat the management is even working to update its supplier list and is switching to some of the new suppliers offering products at a lower price. Reducing human resource needs while automating the inventory system is going to add benefit to the whole SCM system.

Justification of change

M&S procures 98% of the products that its sells from suppliers and so supplier dependency is higher for the company (Mustafeeet al. 2020). Over these years the company was procuring most food items outsourced from different regions and for this, the company had to pay higher tariffs under Brexit laws. It is found in the operations and supply chain management assignmentthat it was becoming difficult to manage and look at sustainable programmes that the management was performing with these external suppliers as higher duty rates were adversely impacting the business output. M&S identified that wastage is one of the issues which is acting as a barrier. Food supply chains are creating much of the wastage M&S records for overstock and wastage has remained bad which the company is planning to change through recycling and smart supply to farms for animals (Cole et al. 2019). To reduce further waste the company as per the operations and supply chain management assignmenthas planned to execute carbon-efficient approaches such as anaerobic digestion and compositing. The group is working with its suppliers to remodel food packaging systems and take alternatives to plastics which are combustible. Under the ethical trade model, the group identifies proper employment for suppliers and workers underneath goes. The company maintains certain standards for trades which the suppliers have to follow. This allows the execution of fair employment policies and ethical trade.

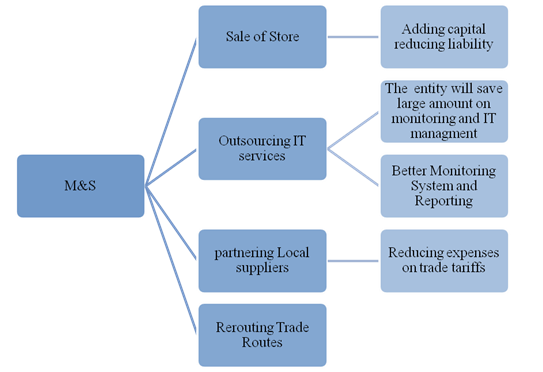

M&S is upgrading its overall working process right from procurement to transport, distribution, stock maintenance, as well display. The management is even aligning suppliers to upgrade their communication system through which live tracking and reporting of productions are possible (Donaldson, 2022). It is found in the operations and supply chain management assignmentthat the organization has been able to pull the business after the last year's Vangrade system through which the organization aimed to reduce waste and improve customer experience. The system was supposed to make better forecasting. The company has saved over £180m through goods costs in the past two years by optimising volume with vital suppliers graded in the silver list (Green, 2021). As per the operations and supply chain management assignmentthe management has successfully worked to reduce costs in packaging as well as rectifying ingredients which are some of the commendable changes. The management says that Brexit has imposed additional tariffs as administration charges for which the company has to pay an extra £42-47m for bulk supplies (Green, 2021). Changes in the routes and sourcing through local suppliers are going to help in saving those extra charges. It is found from the operations and supply chain management assignmentthat the management has categorised suppliers as gold, silver, and bronze as per their involvement in the business and the outputs received from them. M&S assures that good working conditions throughout the supply chain prevail and that each supplier received a fair bidding price as per marker standards. Changes on a high level by selling some of the stores where no output is received and transforming some, such as the store in Hertfordshire is transformed to merchandising and home ware to provide customers latest clothing and furniture. M&S is further outsourcing its back office technology to Tata Consulting Services saving £30m each year (Paul Trudgian. 2022). As per the operations and supply chain management assignmentcost-cutting policies are effective for the company however, it is putting a challenge of monitoring and advocating policies of sustainable practices for which the brand is known.

Flowchart Depicting New Status Quo

(Source: Self-Developed By the Author)

Implementation plan

To improve the business and performance the management of M&S is making some strong decisions. As per the operations and supply chain management assignmentoptimising the products from the source of manufacturing to examine the correct standards of policies are followed by the suppliers or not. The management has planned to develop intermediary stock points where the stocks can shift directly to stores releasing the pressure to maintain a warehouse (Er Kara et al. 2021). This is possible if the management effectively governs supply-demand activity. Smart supply will further reduce wastage from over stock and this in will return benefit to M&S. Apart from that partnering with local suppliers has added advantage to the company which will help in the cost-effective supply of products in bulk quantity. As well transportation costs will reduce if the products are purchased locally. Having local suppliers will gain visibility and monitoring which will escalate sustainable movements. As per the operations and supply chain management assignmentthe management is further planning to develop all its stores under which larger digital displays and viewing areas will give better customer view. Digitised purchase, shifting, stacking and data recording will reduce human involvement at the same time reduce the cost of maintenance; IT services have thus been outsourced.

Conclusion and recommendation

Conclusion

From the operations and supply chain management assignmentstudy it has become evident that supply chain issues have remained a strong section pushing M&S on the back foot in comparison to other companies in the field. Shipment delay and lack of traceability have been identified earlier. Apart from that overstock problems and wastage production from packaging have remained issues. Though the company employed several strategies to tackle the challenges, it is still facing difficulty to meet the price point as others do. Poor monitoring and surveillance as well as falling into long-term contracts with logistics Gist are considered the main reasons for the business to fall. Several strategic developments from acquiring Gist and directly involving in logistics to the supply and distribution of products are considered bold moves. The company apart from that is transferring activities that require high maintenance costs to third parties. It is found from the operations and supply chain management assignmentthat the Group is further working on strategies to reroute supply chains through which costs on tariffs can reduce.

Recommendations

Adopt new strategies that companies such as Walmart are using in the supply chain process.

Develop human resources to tackle effective changes and produce better results.

Develop marketing strategies to gain customer interest and provide them with offers to compete in the market.

Work on smart supply and track livestock results before supplying goods. Overstocking not only reduces demand for the product, but even the maintenance cost also goes high. It is analysed from the operations and supply chain management assignment that overstocking of non-durable items, especially food products is risky.

Better forecasting technology to assume market demand as well as develop intelligent procurement of resources which can cater for products in demand to supply quickly is required.

References

Alshurideh, M., Kurdi, B., Alzoubi, H., Obeidat, B., Hamadneh, S. and Ahmad, A., (2022). The influence of supply chain partners’ integrations on organizational performance: The moderating role of trust. Uncertain Supply Chain Management, 10(4), pp.1191-1202.

Bbc.com, (2021).”M&S warns of new food supplies threat as Brexit rules change” Available at: https://www.bbc.com/news/business-58462351[Accessed On: 01.12.2022]

Birasnav, M. and Bienstock, J., (2019). Supply chain integration, advanced manufacturing technology, and strategic leadership: An empirical study. Computers & Industrial Engineering, 130, pp.142-157.

Birasnav, M., Chaudhary, R. and Scillitoe, J., (2019). Integration of social capital and organizational learning theories to improve operational performance. Global Journal of Flexible Systems Management, 20(2), pp.141-155.

Cips.org, (2022). “How M&S will save millions by 'taking control' of its supply chain” Available at: https://www.cips.org/supply-management/news/2022/july/how-ms-will-save-millions-by-taking-control-of-its-supply-chain/[Accessed On: 01.12.2022]

Cole, R., Stevenson, M. and Aitken, J., (2019). Blockchain technology: implications for operations and supply chain management. Supply Chain Management: An International Journal.

Corporate.marksandspencer.com, (2022). “Corporate strategy” Available at: https://corporate.marksandspencer.com/sustainability/human-rights-our-supply-chain/supporting-our-food-supply-chain [Accessed On: 01.12.2022]

Donaldson, A., (2022). Digital from farm to fork: Infrastructures of quality and control in food supply chains. Journal of Rural Studies, 91, pp.228-235.

DuHadway, S., Carnovale, S. and Kannan, V.R., (2018). Organizational communication and individual behavior: Implications for supply chain risk management. Journal of Supply Chain Management, 54(4), pp.3-19.

Er Kara, M., Ghadge, A. and Bititci, U.S., 2021. Modelling the impact of climate change risk on supply chain performance. International Journal of Production Research, 59(24), pp.7317-7335.

Esoimeme, E.E., (2020). Using the risk-based approach to curb modern slavery in the supply chain: The Anglo American and Marks and Spencer example. Journal of Financial Crime.

Green, W. (2021). M&S working to improve outdated supply chains. Supply Management. Available at:https://www.cips.org/supply-management/news/2021/may/ms-working-to-improve-outdated-supply-chains/

Green, W. (2022). How M&S will save millions by taking control of its supply chain. Supply management. Available at:https://www.cips.org/supply-management/news/2022/july/how-ms-will-save-millions-by-taking-control-of-its-supply-chain/

Kabiraj, S., (2022). Implementing Industry 4.0 Concepts to a Media Content Supply Chain and a Food Processing Business: Case Studies from Finland. Supply Chain and Sustainability Research: SCSR, 1(1), pp.14-26.

Kochan, T.A., Yang, D., Kimball, W.T. and Kelly, E.L., (2019). Worker voice in America: Is there a gap between what workers expect and what they experience.ILR Review, 72(1), pp.3-38.

Logisticsmanager.com, (2022). “Marks and Spencer cites supply chain issues as sales drop” Available at: https://www.logisticsmanager.com/

marks-and-spencer-cites-supply-chain-issues-as-sales-drop/[Accessed On: 01.12.2022]

Marusak, A., Sadeghiamirshahidi, N., Krejci, C.C., Mittal, A., Beckwith, S., Cantu, J., Morris, M. and Grimm, J., (2021). Resilient regional food supply chains and rethinking the way forward: Key takeaways from the COVID-19 pandemic. Agricultural Systems, 190, p.103101.

McGrath, P., McCarthy, L., Marshall, D. and Rehme, J., (2021). Tools and technologies of transparency in sustainable global supply chains. California Management Review, 64(1), pp.67-89.

Mustafee, N., Harper, A. and Onggo, B.S., (2020), December. Hybrid modelling and simulation (M&S): driving innovation in the theory and practice of M&S. In 2020 winter simulation conference (wsc) (pp. 3140-3151). IEEE.

Paul Trudgian. (2022). Marks and Spencer “shakes Up” Its Supply Chain. Supply Chain Consultancy. Available at: https://www.paultrudgian.co.uk/marks-spencer-shakes-supply-chain/

Schleper, M.C., Gold, S., Trautrims, A. and Baldock, D., (2021). Pandemic-induced knowledge gaps in operations and supply chain management: COVID-19’s impacts on retailing. International Journal of Operations & Production Management, 41(3), pp.193-205.

Statista.com, (2022). “Most popular department and home stores in the United Kingdom (UK) as of 2nd quarter 2022” Available at: https://www.statista.com/statistics/968058/most-popular-department-home-stores-uk/[Accessed On: 01.12.2022] Statista.com, (2022). “Revenue of Marks & Spencer worldwide from financial year 2010 to 2022” Available at:https://www.statista.com/statistics/413349/group-revenue-marks-and-spencer-mands/ [Accessed On: 01.12.2022]

Sunny, J., Undralla, N. and Pillai, V.M., (2020). Supply chain transparency through blockchain-based traceability: An overview with demonstration. Computers & Industrial Engineering, 150, p.106895.

Varsakelis, C, Stosch, MV, Dessoy S, Pysik A. (2020). A mathematical model of decision making for investment in process modeling& simulation. INTERNATIONAL CONFERENCE OF NUMERICAL ANALYSIS AND APPLIED MATHEMATICS ICNAAM 2019. Available at:https://www.researchgate.net/figure/Flow-chart-of-assessment-plan-for-M-S_fig3_347203287

Wang, Y. and Hou, G., (2020). A duopoly game with heterogeneous green supply chains in optimal price and market stability with consumer green preference. Journal of Cleaner Production, 255, p.120161.