Analyzing Effectiveness Of Gucci Supply Chain Management

Question

Task: Analyze the effectiveness of the four key flows (in the Gucci supply chain management), the make process and the supply chain forecasting?

Answer

1. Introduction

Gucci supply chain management is the business network in which several people or entities work together to create the finished product from the movement of raw materials. The finished product is finally delivered to the customer end. It is responsible for both direct and indirect fulfillment of the customer requirement. It also involves a broader range of activities that are important for planning, controlling, and executing the flow of a product from the raw materials to final distribution to the customer. The processes are crucial and encompass the planning integration that is needed to optimize the material flow.

This project is about the "supply chain" methodology of Gucci (Fashion Products Organization). It is an Italian brand for fashion and different types of leather products. The organization relies on a selected network that includes trustworthy suppliers. All the suppliers of Gucci work with a strong communication method to ensure the best practices over the "supply chain." I am the "supply chain" manager of Gucci and need to improve the SCM ("Gucci supply chain management") of the brand. The Gucci supply chain management includes thousands of employees to manufacture and produce the collection of the brand. The main goal of this project is:

- Analyzing the different types of the effectiveness of Gucci supply chain management

- Analyzing the effectiveness of production plans of Gucci

- Reviewing the different models of "Supply Chain" forecasting and the effective forecasting methods of Gucci.

2. The Key flows in Supply Chain

The supply chain is considered as the "management of flows." For the "supply chain" network there are four flows that are considered for importance. The flows are:

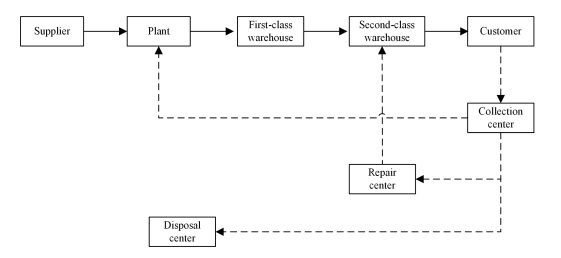

a. Product flow-It is the movement of the materials from the supplier to the customers. The process includes both internal and external and operates with the "customer service." Gucci includes several entries like suppliers, manufacturers, distributors, wholesalers, retailers, and customers. Acquisition of product flow takes place in every stage from its previous stage known as the entire product flow across the "supply chain”. It is recommended that Improving and increasing the distribution network could enhance the product flow of Gucci. This flow of materials or services is generally downstream which begins from the source point to the customer point. Moreover, the upstream flow is associated with the return of the materials or products.

b. Cash or financial flow-It is the financial or economic aspect of the Gucci supply chain managementthat is required to consider from the "investment perspective" and the fund flow perspective. Investments and costs move the "supply chain" forward and optimize the total cost of the chain to improve the profitability (Liu, Rezaei, Wong, & Azami, 2019, p. 1). Financial funds are also known as the revenue and flow from the customer end and considered as the source point of "real money" across the "supply chain." Moreover, the cash flow is considered one of the significant key flows of the Gucci supply chain managementand directly impacts the business profitability of Gucci.

Figure 1: "Supply Chain Structure" (Yang, Wu, & Shi, 2019)

c. Information Flow-SCM ("Supply Chain Management") includes higher operating phases of variable information like the bill of the raw materials, pricing, order information, product data, and the different levels of inventory. Information flow is considered as one of the significant flows across the "supply chain" of Gucci as it provides the detail of the product and financial flows of the organization (Farajpour & Yousefli, 2018, p. 1).Along with that, it also involves the information regarding the supplier and the and the distributor, status of the delivery, and other important documents. The "supply chain" efficiency of Gucci could be improved by increasing the speed of information flow with the help of IT ("Information Technology") to increase the performance.

d. Return Flow-Effectiveness of Gucci supply chain managementis measured with the flow of OTD ("on-time delivery") metric. It is a measurement of the chain that focuses on ensuring the product delivery to the customer end is efficient from the time of order placing. The responsibility of the "supply chain" never ends with delivering the product to the customer. It may be returned due to several reasons like the wrong product or damaged product or mismatch in the product description. It could be referred to as the undesired event in the "Gucci supply chain management" (Ivanov, Pavlov, Pavlov, & Sokolov, 2017, p. 2). In such issues, Gucci needs to organize the shipping method of the returned product for performing various experiments like testing and repairing of the product. Return flow could be improved by pre-testing the product and providing the exact match of the product with the description.

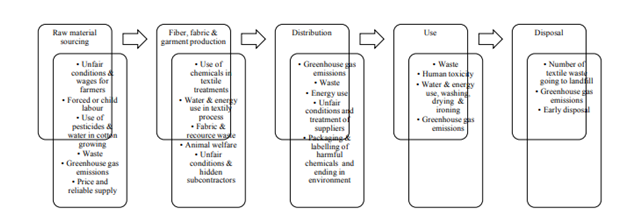

Figure 2: Fashion Industry "Supply Chain" (Marefat, 2019, p. 26)

3. What is the role of the make process in Gucci supply chain management?

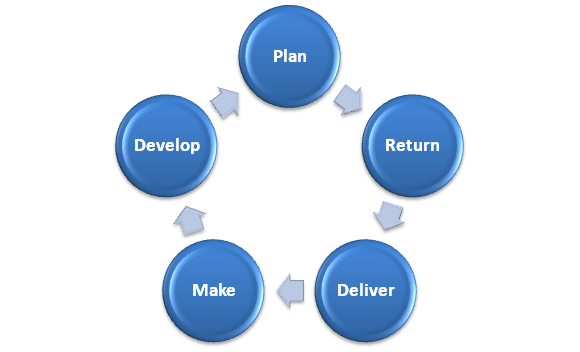

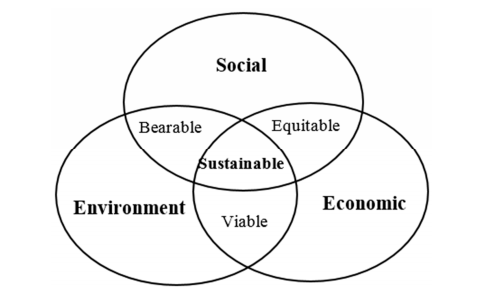

The production planning refers to the manufacturing and production processes of the organization. It includes allocating resources to the employees, raw materials, and the capacity of production. Along with that, the making process also focuses on minimizing the production cost to meet the customer demand for the future days (Mateo, Pla, Solsona, & Pagès, 2016, p. 3). The requirement of an effective supply chain is crucial for Gucci due to a higher variety of products. Along with that, sustainability is also an important factor to maintain the green "Supply Chain Management" (Cai & Choi, 2020). It also needs strict time management to achieve organizational profitability. Most of the organizations dealing with fashion products the majority of their product range in each season to increase their sales. Another important factor that requires high attention is the selling period. The period is considered short and there is no potential for developing and marketing a product late in the market. The making process needs a JIT ("Just In Time") production so that the supply chain could deliver the products before time to the destination(Poh & Liang, 2017). Preserving the traditional style of craftsmanship, the company restructured Gucci supply chain managementthat provided agility to the organization. As each of the fashion products are required to be re-invented by the majority. The production planning and make process could not be strategized and planned with detail in advance. There is also a potential of risks to manufacturing a larger quantity of new products in advance as it could differ from the actual plan.

"Supply Chain" efficiency is a crucial factor to avoid the "out of stock" issue. The making process of Gucci supply chain managementis followed by three key processes such as:

- Preparing collection-Manufacturing small quantities of the product for use in fashion shows. This provides information about future demand for the product.

- Order management-Collecting orders from several fashion shows, distributors, agents, and various third-party sources.

- Planning-Formulating the "production plan" that is associated with the pre-season marketing plan.

Production planning of Gucci begins with the allocated budget for the season which is represented with the trends of traditional sales. The purchasers could reach to the majority of the extent for the requirement that has been planned. This mainly focuses on the color of the items that have been ordered. The responsibility for these orders goes to the material suppliers and the other contractors and sub-contractors that require higher efficiency in the supply chain to deliver the order within time. If these raw material resources could be arranged from the internal sources of the organization, the business profitability will increase for the organization. The suppliers of Gucci are allowed to follow the request from the market and need to respond rapidly depending on their capacity. It limits and restricts the supplier's capability to control the total set of processes which results in uncertainty for delivering the orders. Gucci has several types of production planning that depends upon the CODP ("Customer Order Decoupling Point"). The CODP describes the non-generic point of the production. However, it is always dedicated to the specified orders from the customers.

Figure 3: "Supply chain" make processes (Created by Author)

Figure 4: Three pillars of "Supply Chain" (Poh & Liang, 2017)

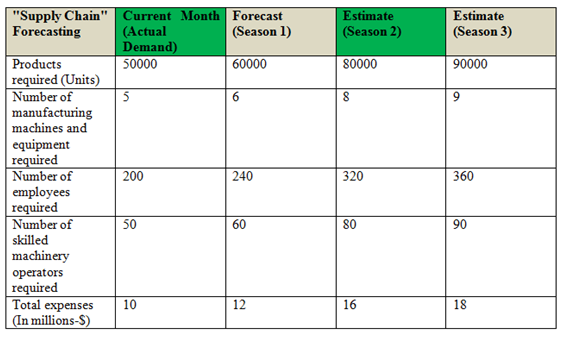

4. Supply Chain Forecasting

SCF ("Supply Chain Forecasting") involves complex issues like Co-ordination and information sharing between different stakeholders. Gucci supply chain management includes both direct and indirect parties to fulfill the request and orders of the customers. "Party" could be referred to as a "decision-making" unit of the overall chain(Syntetos, Babai, Boylan, Kolassa, & Nikolopoulos, 2016). It has several extensions from the level of customers throughout several distributors, whole-sellers, or retailers. The extension returns to the raw material suppliers and the manufacturer (Gucci).

SCF models include several qualitative techniques like market research, personal insight, or sales estimates. Along with that, the quantitative methods also exist in SCF like the "Graphical Forecasting Models" and the "Trend Forecasting Models." Among both of these models market research is an excellent approach for the qualitative type of SCF as it provides the target market information to Gucci supply chain managementwith a detailed overview of customer demands. Moreover, among the quantitative model approach for SCF, the "Trend Forecasting Model" is the best approach for the organization that provides the information about the latest trends that are gaining popularity across the market and having a higher demand value regarding the customers.

The frequency of product demand could be referred to as the key concept of the SCF. The origin and properties of the demand depend on the feature of the "Supply Chain." The value generated by the "supply chain" creates the difference between the worth of the finalized product and the expenses that the Gucci supply chain management experiences to meet the customer demands(Syntetos, Babai, Boylan, Kolassa, & Nikolopoulos, 2016, p. 5). However, these expenses may be environmental as well as organizational costs. The SCF plays a crucial role in improving this core value as the maximized operating function of such types of uncertainty is associated with the customer demands of Gucci.Scholars considered that SCF is a critical factor regarding the planning and operations of sales of the products. The forecast is typically depended on the documentary information from different departments of Gucci. It has been noticed that some of the information posits to a "predictive key-value" but it could be applied to all of the information (Fildes, Goodwin, & Önkal, 2019, pp. 1, 2). SCM ("Gucci supply chain management") always focuses on the product flow and other information and services from source to the destination according to the parameters of their demand and capacity. This makes a sense that SCF is the key approach that is useful to address the uncertainties across the SCM. Analysis techniques provide the extracted SCF data by identifying the relationship of the demand across the network of the chain (Seyedan & Mafakheri, 2020).The average competitors of Gucci carry over the majority of new products in each season which is a greater advantageous factor across the competitive market. Regarding the market factors, the Gucci supply chain management is quite efficient, and it could be improved with the internal resource department to increase the business profitability and speeding up the efficiency of the "supply chain."

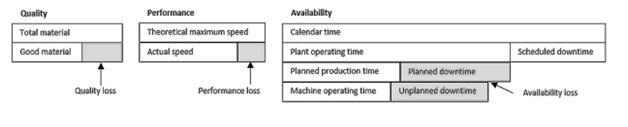

Figure 5: "Supply Chain Effectiveness" (Plinere & Aleksejeva, 2019, p. 2)

Figure 6: "Supply Chain Forecast" Model (Created by author)

5. Conclusion

This project discusses the different "supply chain" processes related to the Italian fashion brand Gucci. Gucci is one of the global leaders in fashion collections and requires several improvements regarding its "Gucci supply chain management". The different key flows of SCM have been clarified related to the fashion brand like the product flow and financial flow. The effectiveness of the making process and production planning has been briefed regarding the current scenario. Moreover, the different models of "Supply Chain Forecasting" and their effectiveness has been discussed with the justification and theoretical concepts related to Gucci supply chain management.

Bibliography

Cai, Y.-J., & Choi, T.-M. (2020). A United Nations’ Sustainable Development Goals perspective for sustainable textile and apparel supply chain management. Gucci supply chain managementTransportation Research Part E: Logistics and Transportation Review, 141, 102010.

Farajpour, F., & Yousefli, A. (2018). Information flow in supply chain: A fuzzy TOPSIS parameters ranking. Uncertain Supply Chain Management, 6(2), 181-194.

Fildes, R., Goodwin, P., & Önkal, D. (2019). Use and misuse of information in supply chain forecasting of promotion effects. International Journal of Forecasting, 35(1), 144-156.

Ivanov, D., Pavlov, A., Pavlov, D., & Sokolov, B. (2017). Minimization of disruption-related return flows in the supply chain. International Journal of Production Economics, 183, 503-513.

Liu, Q., Rezaei, A., Wong, K., & Azami, M. (2019). Integrated modeling and optimization of material flow and financial flow of supply chain network considering financial ratios. Numerical Algebra, Control & Optimization, 9(2), 113.

Marefat, S. (2019). Pursuing supply chain sustainability in the luxury industry.

Mateo, J., Pla, L., Solsona, F., & Pagès, A. (2016). A production planning model considering uncertain demand using two-stage stochastic programming in a fresh vegetable supply chain context. SpringerPlus, 5(1), 839.

Plinere, D., & Aleksejeva, L. (2019). Production scheduling in agent-based supply chain for manufacturing efficiency improvement. Procedia Computer Science, 149, 36-43.

Poh, K., & Liang, Y. (2017). Multiple-criteria decision support for a sustainable supply chain: applications to the fashion industry. Informatics.4, p. 36. Multidisciplinary Digital Publishing Institute.

Seyedan, M., & Mafakheri, F. (2020). Predictive big data analytics for supply chain demand forecasting: methods, applications, and research opportunities. Journal of Big Data, 7(1), 1-22.

Syntetos, A., Babai, Z., Boylan, J., Kolassa, S., & Nikolopoulos, K. (2016). Supply chain forecasting: Theory, practice, their gap and the future. European Journal of Operational Research, 252(1), 1-26.

Yang, D., Wu, D., & Shi, L. (2019). Distribution-Free Stochastic Closed-Loop Supply Chain Design Problem with Financial Management. Gucci supply chain managementSustainability, 11(5), 1236.