Asda Case Study : Operations And Supply Chain Management

Question

Task:

Create Asda case study focusing on a problem relevant to Operations Strategy/Management or to Logistics & Supply Chain Strategy/Management.

Please see below an indicative (but not exhaustive) list based on the content of the module:

- Processes Analysis and Facilities Layout - Logistics and Distribution Strategies

- Estimation and Demand Forecasting - Inventory Management

- Distribution and Warehousing - Performance Measurement

- Application/Implementation of new technologies (Big Data, Internet of Things, Drones, 3D Printing, Augmented Reality, Artificial Intelligence etc.)

- Quality Management

- Project Management

By constructively utilizing the knowledge gained during the course and through your extensive independent reading, critically discuss and analyze the pertinent issues in the case study of your choice.

Answer

Executive Summary

The Asda case study has provided a brief focus on the supply chain issues that may be caused due to transportation and logistics. the report will also provide detail on the project to deal with the issues. This report suggests the resolution of problems relating to business, supply chain and financing operations for the company of Asda, especially during the worldwide Covid 19 pandemic. It mentions ways in which these issues have affected their business. It also portrays various mitigation strategies that were implemented by the company of Asda. This report provides first-hand documentation of ways that have helped Asda recover from the setbacks caused by the pandemic.

1. Introduction

The supply chain has been one of the greatest elements within the activities or functioning of the company. It initiates with manufacturing to selling to the end-user of the product. Any shift within the operation may impact the supply chain of the company thus affecting its operations and brand value. logistics is one of the main issues within the supply chain operations that impact the supply chain function. the portrayal of logistics and other concerned matters will be presented within the report. In this, report the impact of transportation and logistics on the supply chain will be presented and its effect on the company’s operations.

2. Selected company

Figure 1: Asda Branding and Storefront

(Source: asda.com, 2022)

Asda Stores Ltd. generally portrayed as ASDA is considered a British supermarket chain. the supermarket has its headquartered in Leeds, England. The company was originated in the year 1949 when the Asquith family has merged the retail business with the Associated Dairies company of Yorkshire. Then it was expanded within Southern England in the 1970s and 1980 (asda.com, 2022). The supermarket chain has developed its operations across the Uk and provides online support in supplying groceries. this has resulted in providing greater value to the services provided by them.

3. Description of the current situation

3.1 Brand Situation and Market Value

The business model of Asda has allowed in undercutting the competitors upon price whilst providing excellent quality. The brand being created was dependent on the notion of ‘The People’s Champion’ a positioning that capitalizes on Asda’s heritage being cooperative and a desire of always being on the side of the customer. The share of Asda has grown as one of the fastest brands within other market brands and has been beating their competitors at a rapid pace. Currently, the supermarket chain Asda's distribution network has resulted in a sale of £1.7billion for the billionaire Issa brothers and investment firm TDR capital (Fengyi, 2021). The sale price is £500million in comparison to the expected sale. This entails 21 food depots, three centres concerning the George clothing range and two concerning 'general merchandise' non-food goods like lightbulbs. It also entails two centres concerning imported goods and two linked to handling customers' online orders.

3.2 Issue faced by the company and its impacts on supply chain

The shortage of drivers in the period of covid 19 pandemic and its implications has resulted in a shortage of drivers within the company. this in turn has impacted the stores to be incomplete with the goods. this again impacts the current supply chain of the company. Due to the driver shortage, the supply of goods in Asda store has been ineffective and customers are deprived of the requirement of goods. There have been also the issue of thousands of truck drivers have compelled to do a strike after the rejection of pay rise. The Freight Transport Association has provided an estimate that presently there is a shortage of 60,000 drivers across the UK (Venegas Vallejos, et al. 2020). In view of the issues of Asda, The government has been fast-tracking HGV licensing processes for getting more drivers for the company. The situation caused by the shortage of drivers has resulted in problems to the suppliers that in turn has affected the distribution network of Asda.

3.3 Financial losses due to the problem

Asda has been asking the suppliers that utilize the collection service for favouring the 5 % rise within the payments within the transportation cost and with the shortage of drivers. Due to this, Asda has resulted in poor performance of their activities as the sales of developed stores have fallen by 5.8% (Kuijpers, et al. 2018). with the shortage of the driver, the sales got held for a long period and the supply chain was also disrupted and which resulted in impacting the sales growth. the sales growth tumbled as it affected the sales in such a period when the festivities were about to begin. the issue of driver shortage has given a big drawback to the company, impacting the supply of goods and presenting a poor financial performance. This has given a major setback to the company as has been focused on setting a strategy to hike the sales growth and fulfilling the demands of the customer.

3.4 Logistical processes in places within the brand

the logistic procedure of Asda consists of very heavy operations and the operations are very much dependent upon the logistics procedure for the distribution of goods. Ranging from Warehouse to HGV Driver roles, Logistics within Asda is portrayed as an exciting place. The logistic distribution selects and deliver quality goods by depots throughout the nation to every located store and developing the online business. the logistic facilities also possess a parcel delivery service, ToYou, connecting the customers to their favourite brands online. the shortage of drivers has resulted in affecting the use of the supply chain and the transportation chain has also fallen by a huge restriction upon the services. This has affected the brand value of the company in providing value to the customers.

4. Possible solution

4.1 Analysis of potential solutions and change implementations

The various solutions for change implementations to improve supply chain and logistical processes are as follows:

Implementation of Automation in the Supply Chain Mechanism

In the purview of driver shortage in the present supply chain management procedure of ASDA, it has been acknowledged that the ageing drivers are very soon going to be retired by an increase of 15%. The possible solution to this huge shortage of around 90,000 drivers among which 26,000 are truck drivers that are directly associated with the supply chain management and logistical support to the supermarket's delivery mechanism is the implementation of automation in the delivery system. As it is already reported that the UK is facing a serious labour crisis for the last decade, there is enough space to implement the cost-effective and efficient automation process in the successful delivery mechanism of food and other grocery items to the customers (Bristolpost.co.uk., 2022). It could be implemented with the proper application of an autonomous delivery mechanism with self-driving vans. It has been envisioned due to the successful venture of Amazon’s ‘Just Walk Out’ technology that recently occupied the market with a new Fresh Store in West London. The idea could be cherished by ASDA also to implement it in the delivery mechanism to mitigate the driver shortage problems that posed a great threat to the operability of the SCM of the supermarket.

Financial assistance of 1 million pound

In the backdrop of the present supply chain management and logistical crisis that has paralyzed the entire delivery mechanism of ASDA in recent years, there is a critical urgency concerning the financial assistance to the people with proper encouragement. As the current labour strength of drivers is getting old and within the next 5 years companies could witness a huge problem concerning its delivery process, ASDA announced a scheme of 1 Million pounds for the persons who choose to become truck drivers and work for the company (Paul, 2022). The benefit will not only provide financial security and pension but there would be medical and educational facilities from the company to the persons opting to be a driver for ASDA in the long run. It could be a great short-term solution to the present crisis and with effective implementation, it could increase the number of drivers that are currently operating in the company.

4.2 Proposing one specific change that needs to be implemented

In the above context, proposing one specific change could be difficult considering the span and scope of the crisis. However, there could be some measures that could be taken immediately to mitigate the problem to some extent. The specific change regarding the mechanism for more testing facilities for HGV truck drivers through AI needs to be implemented concerning the delivery process and customer-to-company contact process. The effective implementation of Artificial Intelligence (AI) or Automation could be really helpful in this regard to reduce the problem to a great extent considering its possible extent (Murray, 2022). The user-friendly interface of an online application is very viable to attract customers' attention in the fact that the company is paying enough attention to their customer's satisfaction and demands. The replica of Amazon could be implemented differently so that there is a unique trademark of ASDA regarding that process.

5. Proposal of a new procedure or change

5.1 Justification for choosing the solution or improvement

The first justification is obviously due to the high effectiveness and penetrating capacity within the customer base within a very short period. The effective justification could be understood regarding the choice considering its span of working and precise accuracy in the working process. The AI-supported automation would be very efficient in solving the current issues through digital platforms. The concerns of truck drivers regarding working procedures, training, and testing processes could be all sought out through the support of automotive mechanisms (Butt, 2021). The possible situations caused due to the huge driver shortage in the company could be mitigated through the successful autonomous self-delivery mechanism supported by automation technology and artificial intelligence. The combination of both AI and automation could have been the best way to solve or improve the present supply chain crisis within the company.

The second justification is regarding the time frame of the solution. Compared to any other solutions that are available regarding the present crisis it is very time-consuming and costly. That is why instead of investing money on time-consuming and long-term projects the effective implementation of automation Technology with the support of AI could be time-bound and cost-effective. In addition to that, it could be thoroughly measured and checked without any prior concern of other authorities by the company itself to monitor the supply chain management process (The Guardian, 2022). It could be said that this process will justify the cause of beneficial and business-friendly e-solution compared to other alternatives.

5.2 Reasons for rejection of the other solutions

The first reason is associated with the financial aspect of the business. Though ASDA has announced a scheme worth 1 million pounds, there are several obstacles in the path of the company to implement long-term changes due to the economic crisis faced by the UK after the BREXIT deal and the repeated outbreak of COVID-19 in the country. Due to the BREXIT, many truck drivers were forced to leave the country due to unequal working conditions and other constraints. Around 135,000 out of 275,000 are above the age of 50 (Chen et al. 2022). It is now impossible to recruit so many truck drivers within a short period. That is why no bonus or alliance measure is suitable in this regard.

The second reason behind the rejection of other solutions is the unavailability of resources and lack of diversity within the industry. The alternative measures other than the implementation of AI-based automation service in the delivery process could be very time-consuming, costly, and less diverse compared to the current one. With the effective implementation of an AI-based support system for the testing and training of new truck drivers, the time frame could be reduced compared to any other possible solutions in this context (Razak et al. 2021). The other solutions could not be effective enough due to the high tenacity of financial liability and security concerns whereas the mentioned solution or change in the implementation would solve the purpose of both with quick response time.

6. Description of the new situation in the company

6.1 Impact of new situation on existing processes

Through the implementation of a new process to the existing mechanism the first change could be seen as a fully digitized and automotive delivery mechanism concerning logistics and overall supply chain management. It is responsible to bring an innovative technological aspect to the delivery mechanism of the company which was not followed earlier (Do et al. 2021). Similarly, the second change regarding the new situation is associated with the overall working condition and effectiveness of the total work done by the organization workforce. The new process is responsible for bringing a definitive change regarding the scheduling of supply chain mechanisms and logistical support in comparison to the earlier process. At last, the change in working behaviour of employees and the managerial process could be witnessed through proper implementation of this change. The supply chain management could get enough support from the applicability of automation through the delivery and Logistics support (Do et al. 2021). The supermarket change could get a larger distribution network compared to earlier after the successful implementation of automation.

6.2 Process flow-chart

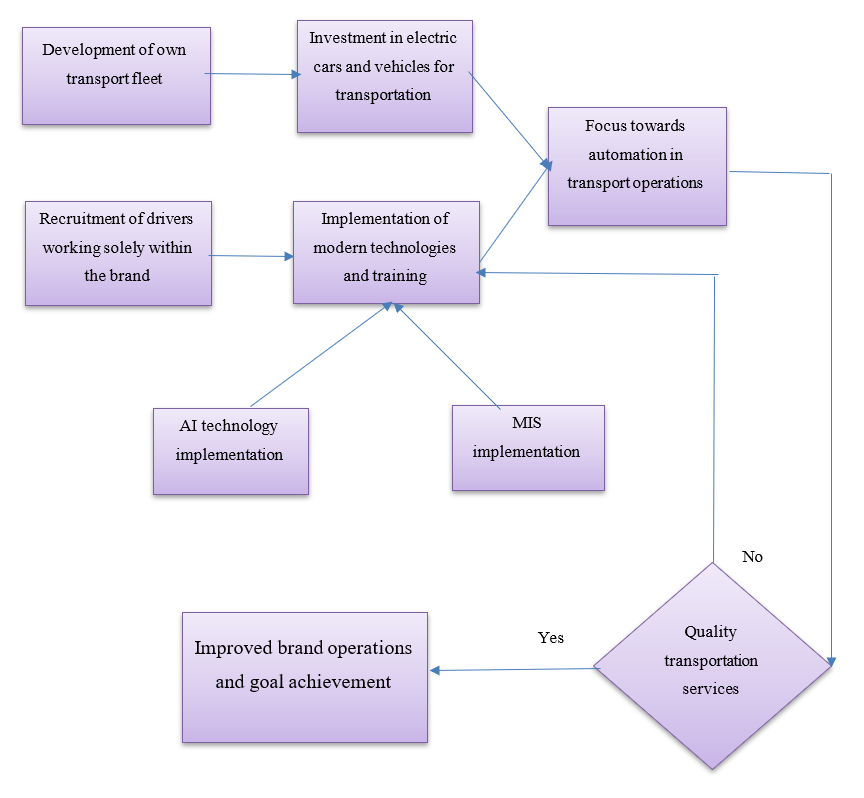

Through the flow chart, the new process is depicted with precise accuracy and intricate measures. It could be understood that the flowchart is responsible to represent an overview of the upcoming process that would change the present mechanism of the company regarding the issue of the driver shortage. Through the flowchart, the effective implementation of automation Technology with the support of AI is depicted with its relationship to the supply chain mechanism of ASDA, concerning the delivery process to its customers.

6.3 Differences in employee activities

The first difference within the activities of employees after the implementation of the change is associated with the functionality of the organizational framework and its related obligations. With the effective implementation of automation and AI Technology, the work of employees could be easy to handle with a new very minimum support mechanism (Venegas Vallejos et al. 2020). As it is reported that the UK is going through a labour shortage concerning supply chain mechanism and also organizational basis automation could be effective in reducing the overall burden of the workforce to mitigate various works simultaneously.

- Apart from the reduction in work burden, the new situation could bring different opportunities for the employees in different shapes. Employees could be trained with the automation technology to get proper education on the operations and functionality of the process which could result in better supply chain management concerning the delivery mechanism of ASDA (Venegas Vallejos et al. 2020). The truck drivers that are currently working could be trained with the technology to get an effective idea of GPS and other network-based Technologies to reach customers' locations at the proper time without any delay.

- In addition to the above differences, there is a specific change in attributes within the mindset of employees that could be beneficial for the productivity and management of supply chain mechanisms for the long run. The present working condition could get better with the implementation of automation and also the truck drivers could get proper rest and financial assistance due to this change in the mechanism (Venegas Vallejos et al. 2020). It is to be noted that the permanent dissolution of physical labour could not be a reality at any cost but the effective balance between automation technology and physical labour could be viable enough to benefit both employees and the company management.

7. Justification of change

7.1 Analysis showing specific improvements in financial operations

Owing to the crisis due to the worldwide Covid 19 pandemic, the company of Asda had faced a lot of setbacks relating to their availability and delivery of services which led to a tremendous impact on their financial scenario. The main reason behind delayed deliveries and procurement of resources was a shortage of manpower. Given the situation of lockdown, many people were unable to work leading to other problems faced by the UK-based company of Asda (Ibrahim and Wang, 2019). The company operators had to implement newer strategies to recover from such issues and restore proper financial management among other challenges. The officials of Asda decided on recruiting their delivery services so that the potential customers can receive the products or services they ordered within specific time intervals. They also implemented online delivery services making life easier for their consumers during such difficult times. The lack of manpower retards the completion of various important tasks and therefore must be managed accordingly so that it might align with pre-set organizational objectives. Asda even decided on recruiting their other employees in delivering products during times of emergencies which was quite often due to the global pandemic. These significant measures were taken by the company of Asda (Chen, et al, 2022).

The delivery of products nationwide or even abroad was made possible owing to the accessibility of different modes of transport such as air and water routes. The company of Asda worked on enhancement of the training process to complete the tasks related to obtaining materials, their storage and finally delivering them to the respective customers. This had helped them reshape their financial status and prioritize significant tasks related to finance management. By accelerating the procurement process, more products were obtained which were later stored in warehouses to avail their packaging. Significant marketing strategies were put to use to deal with competitors existing in the same market. Essential alterations such as credit management, streamlined procedures for transportation and other expenses, affirming of purchase orders and proper outsourcing techniques have helped Asda gain a significant competitive advantage which led to the resolution of potential challenges that were faced during the worldwide pandemic (Meeks and Meeks, 2020). All new processes were carried out keeping in mind significant Covid-related protocols. These mentioned implementations have helped in increasing the competence of workflow of Asda which further led to enhancement of the financial scenario, thereby helping the company recover from possible setbacks as described earlier.

7.2 Flowchart depicting the new status quo

Figure 2: Flow Diagram

(Source: Created by Author)

At first, due to the worldwide Covid 19 pandemic, many employees lost their jobs since there was a significant cut down in the work strength which negatively impacted the company of Asda. Significant changes in the operations and supply chain activities were made for the company to reach normalcy in a not to the normal situation caused by the pandemic. The transportation and delivery facilities were inadequate which delayed the provision of products and services to the potential customers of Asda. They had to implement newer marketing strategies to deal with market-related competition. Next, the availability of online services has made lives much easier for the potential consumers of the company of Asda (Petetin, 2020). The mentioned company even developed their delivery services to provide the products to their respective customers. New routes of transportation were used to provide proper services across the nation and even abroad. Significant changes in the credit management and vouchering of purchase orders have helped Asda reach a decent financial state after the huge impediment caused by the worldwide pandemic. In recent times, the financial status quo is quite adequate for the company since the company operators have managed to recover from the pandemic.

8. Implementation plan

8.1 Gantt Chart

|

TASKS |

Week 1 |

Week 2 |

Week 3 |

Week 4 |

Week 5 |

Week 6 |

Week 7 |

Week 8 |

|

Development of aim and objectives |

||||||||

|

Tracking change requirements |

||||||||

|

Developing an action plan for the change implementation |

||||||||

|

Approval of the plan by the board of directors or steering committee |

||||||||

|

Execution and implementation of change |

||||||||

|

Use of AI and MIS technologies for innovative developments |

||||||||

|

Monitoring issues or possible impacts on goals |

||||||||

|

Closing the change project |

8.2 Activities and Time-frame for operations

|

Important Activities |

Time Required |

|

Procurement of resources. |

2-4 days |

|

Storage in warehouses. |

1 day |

|

Marketing. |

5 days |

|

Packaging. |

1-2 days |

|

Delivery of products. |

Approximately 3 days to 2 weeks owing to distance difference. |

|

Feedback from customers. |

1- 10 days |

Significant policies were implemented for proper obtaining of resources for the manufacture of products and buying of various products to resell to the customers. The next step involves storing those materials in warehouses, which is a very important phase followed by marketing and packaging. They are later delivered to respective customers in return for their feedback.

8.3 Milestones and Deliverables

The report developed has been focused on achieving a resilient supply chain within the operations of the company that will fulfil the objectives of the company. The shortage of drivers needs to be sorted out for carrying out an effective and resilient supply chain for the company (Almughairy, 2021). This has called for setting a strategy to achieve the objectives of setting effective transportation proves to carry out the supply chain. The deliverables will be focused on designing an effective transportation process to achieve the milestones of an effective supply chain for the company.

8.4 Plan of Action

the plan of action consists of setting a strategy that will help Asda in conducting the transportation operations by eradicating the issue of shortage of drivers. To boost their distribution facilities across the stores there is a need of setting the right strategy that will help the company in facilitating the strategies that will help in boosting the transportation issue and enabling the supply chain easy and effective. Recruit more and more drivers by Asda will help them develops their supply chain functioning. By recruitment of more drivers will also hike the sales growth of the company and fulfilling the demands of consumers.

9. Recommendations

Abiding by the recent Covid-related protocols is extremely important for businesses like Asda to continue their services and enable proper financial management. Monitoring all significant expenses can help in comprehending various issues related to finances. Enhancement of supply chain operations can help in better storage of products. All business-related operations had undergone various alterations due to the global pandemic. Similarly, Asda is expected to develop new objectives that align with Covid-related protocols. This can help the company retain their financial status quo and offer its services nationwide as well as abroad. Implementation of sustainable practices can help the mentioned company to attract more customers who are conscious about environmental needs, thereby providing the proper service. By determining the respective needs of the consumers, Asda can help in keeping their customers satisfied which further leads to company profitability. Improvement in warehousing is one of the most important aspects, especially in recent times since Asda is beginning to recover from major setbacks caused due to the pandemic. The company should pay greater attention to the feedback, both positive and negative, from their customers which can allow them to improve the available services. These are the significant recommendations for this particular report.

10. Conclusion

This report is based on operations and supply chain management for the company of Asda, relating to significant changes that Asda had undergone owing to the global Covid 19 pandemic. It defines the challenges faced by Asda along with ways in which such issues can be resolved. It even describes how all the mentioned problems have affected business in modern times. Significant mitigation strategies were used as gathered from this study which has helped in the management of various tasks. It shows the improvement of workflow as a result of such policies to build better competitive strength for Asda.

Reference List

Almughairy, A., 2021. Managing Multilevel Stakeholder Engagement in Vision and Strategy Making: The Case of Aseer Region. Journal Architecture & Planning, 33(3).

asda.com, 2022 About ASDA Available at https://www.asda.com/about [Accessed 05/03/2022]

Bristolpost.co.uk., 2022. [online] Available at:

Butt, A.S., 2021. Supply chains and COVID-19: impacts, countermeasures and post-COVID-19 era. The International Journal of Logistics Management.

Chen, X., Wang, C. and Li, S., 2022. The impact of supply chain finance on corporate social responsibility and creating shared value: a case from the emerging economy. Supply Chain Management: An International Journal.

Chen, X., Wang, C. and Li, S., 2022. The impact of supply chain finance on corporate social responsibility and creating shared value: a case from the emerging economy. Supply Chain Management: An International Journal.

Do, Q.N., Mishra, N., Wulandhari, N.B.I., Ramudhin, A., Sivarajah, U. and Milligan, G., 2021. Supply chain agility responding to unprecedented changes: empirical evidence from the UK food supply chain during COVID-19 crisis. Supply Chain Management: An International Journal.

Fengyi, Z., 2021. The Analysis of Asda-Sainsbury’s Merger/Acquisition. Journal of Finance Research, 5(1), pp.1-6.

Ibrahim, N.F. and Wang, X., 2019. A text analytics approach for online retailing service improvement: Evidence from Twitter. Asda case study Decision Support Systems, 121, pp.37-50.

Kuijpers, D., Simmons, V. and Van Wamelen, J., 2018. Reviving grocery retail: Six imperatives. Mckinsey, Perspectives on retail and consumer goods Winter, 19.

Meeks, G. and Meeks, J.G., 2020. 11 The impact of M&A on performance. Accounting for M&A: Uses and Abuses of Accounting in Monitoring and Promoting Merger, p.208.

Murray, G., 2022. Asda and Sainsbury’s food distributor goes bust putting 400 jobs at risk. [online] mirror. Available at:

Paul, K., 2022. Driver shortage: Premier Foods calls for army support; Asda says ‘just keeping head above water’ - Business & Industry | News | Analysis

Magazines- Asian Trader. [online] Business & Industry | News | Analysis | Magazines- Asian Trader -. Available at:

Petetin, L., 2020. The COVID-19 crisis: an opportunity to integrate food democracy into post-pandemic food systems. European Journal of Risk Regulation, 11(2), pp.326-336.

Razak, G.M., Hendry, L.C. and Stevenson, M., 2021. Supply chain traceability: A review of the benefits and its relationship with supply chain resilience. Production Planning & Control, pp.1-21.

The Guardian. 2022. UK supermarkets ask suppliers for payments due to driver shortage. [online] Available at:

Venegas Vallejos, M., Matopoulos, A. and Greasley, A., 2020. Collaboration in multi-tier supply chains for reducing empty running: a case study in the UK retail sector. International Journal of Logistics Research and Applications, pp.1-13.

Venegas Vallejos, M., Matopoulos, A. and Greasley, A., 2020. Collaboration in multi-tier supply chains for reducing empty running: a case study in the UK retail sector. International Journal of Logistics Research and Applications, pp.1-13.